Edit

Power Distribution

Edit

India Power Corporation Limited, has been in the distribution business for more than a century now. It is one of the oldest, reliable, service oriented and customer friendly with a competitive pricing structure. IPCL serves various consumer segments ranging from Govt establishments, Industrial houses, Railways to domestic consumers spread across an area spanning 798 sq. kms. across Asansol Raniganj belt in West Bengal, India. The Company maintains one of the lowest T&D losses in the country which hovers around 3% despite its accelerated growth in LT business over the last couple of years, which is lower than the national benchmark, by continuously improving its operational efficiency. This has been achieved through a multi-pronged approach by maintaining better HT/LT ratio, HVDS layouts, multiple power sourcing points, IT interventions through Supervisory Control and Data Acquisition (SCADA), Internet of Things (IoT) & Smart Metering based DT and PT monitoring, ongoing effort to digitize the consumer end-to-end, thereby operating on a near real time data to define, monitor, achieve, improve and control on the operational parameters thereby enhancing reliability and effectiveness of power supply.

Edit

Digital Transformation

Edit

IPCL aims to become smart utility and has become so to a large extent. It started with our customers where we switched from old analog meters to smart meters. To have better control over our network, we have implemented SCADA (Supervisory control and data acquisition) in our distribution business. To monitor its distribution transformers, IPCL installed smart meters and IOT devices which sends data to cloud so that engineers can see the parameters almost at real time. This has reduced outages significantly thus benefitting our customers. IPCL has implemented technical architecture to bring all disparate data to a single repository so that automated and intelligent reporting has become possible. This has made decision makers to see reports and quickly react. We even have automated reports sent to stakeholders every morning. The architecture also allows different smart meter clouds to send data to the single repository thus enriching reporting systems in the company. Similarly, many reporting systems have been revamped and automated. IPCL is climbing up the maturity ladder to handle its data more efficiently. Going forward, customers will get SMS of any outage and get their power usage patterns on their mobile phones. We at IPCL are digitally linking the entire network from feeder to customer.

Edit

IPCL has adopted Business Intelligent (BI) form of reporting system across all levels. For this, it has adopted Tableau, one of the best BI tool in the world in the Company. Further, it has automated all such BI reports at different times in the day to different stakeholders. Hence, the users no longer ask to reports to work on. They get it automatically and know where we stand every day. This has eliminated countless hours in preparing reports and benefitted the company operationally. To develop BI reporting, a technical architecture was implemented by IPCL making it among the first few in the country in power sector to do so.

Some of such reports being generated are Commercial and Technical Dashboards for Management & Business Users, Specific KPI Dashboard for Business Head to monitor day to day business activity, Inventory Dashboard for IPCL procurement team. Stock Consumption pattern monthly and weekly, Consumer Complaint Dashboard for Business Development team to monitor all types of complaints raised by consumers, Outage Management Dashboard for SBU’s Leads and other stakeholders, HT Interruption report to view interruption for Key Consumers (CD>500 KvA), DT Dashboard to view transformers peak load, Oil Temperature, Phase balance etc. Feeder Performance Report for Respective Feeder Managers, Customized Outage report for IPCL Regulatory team etc. This has even helped in timely report to West Bengal Electricity Regulatory Commission (WBERC).

Edit

IOT has been a proven technology in many sectors and power sector is no exception. Various parts of power sector like – Generation, Transmission, Distribution, Renewables etc. have all benefitted from adoption of IOT. Hence, IPCL has leveraged these benefits and adopted IOT in it distribution network. For us, measuring and monitoring the performance of assets such as Transformers are of utmost importance. Gathering some crucial information about transformers like load, temperature etc. on real time basis (or at least on a frequent basis) can make several decision making process faster and efficient.

Edit

Outages in our electrical grid is often a cause of customer dissatisfaction for our customers and are a source of revenue loss for the company. Hence, to reduce outages, it is necessary to reduce response time to the outages so that restoration is as fast as possible. Hence, to reduce these outages, Outage Management System (OMS) has been brought in with the objective of enhancing customer satisfaction and reduce revenue loss. There were many OMS products in the market but either they did not meet our requirement or required high capex. Hence, the digital team at IPCL designed a cost effective solution which is being implemented. With this, IPCL becomes the first Discom in India to design its own OMS from scratch. The solution captures data from IOT devices and smart meters installed in the network and uses them to make technical team monitor them. It also alerts them in cases of outages. The solution captures data on a real-time from the meter at each point, throughout the network and pulls in data to a central data repository, which is integrated with a real-time dashboard for operations/control room team, which shows the following real-time statistics from the Feeder to the Last Consumer in the chain, The Dashboard built on a GIS map and each asset tagged with Geographic Latitude and Longitude helps the Operations team with the following information such as Network asset identification and location on GIS Map, Identification of Impacted Consumers, Load analysis of each Distribution Transformer, Load flow analysis in real-time between source , Distribution and Consumption points, Immediate Identification of areas of concern ( deviation of defined threshold limits), Immediate identification of failure or faults, Notify or alert the Linesman / concerned team for fault and deviation, Keep the Field teams connected via Mobile Application using collaboration as video call & Messaging and finally Create a Knowledge repository of solution provided for future reference storing the case history.

Edit

IPCL has adopted SAP as its core ERP system for over a decade. We continued the SAP journey and further enhanced the consumer experience last year by introducing web portal and consumer mobile apps integrated with SAP. This allowed Consumers to get his/her meter data, commercial information etc. on their finger tips. Operational team at IPCL too benefitted since they too get real time information. SAP integrated online payment collections options were introduced which allowed real time sync on consumer ledger thus enhancing consumer experience.

For billing requirement, IPCL uses SAP IS-Utility software. This too was further strengthened using our maker checker process resulting in more robust roll matrix which help business to run error free environment and ensure compliance effectively.

Stock reservation process was introduced this year which help business to monitor each item of stock in more effective way. It helps business to control over stock utilization. Introduced E-procurement platform to make procurement process automation. Integrated with SAP to flow data from SAP to the procurement platform without human intervention to make procurement process faster in turn help business to reduce the procurement cycle. To make different business process faster and get decisions quickly introduced different automated reports from SAP. These reports are generated to the leadership team which help them to monitor business very effectively and provide their decision faster.

Edit

Digital Security is an important aspect at IPCL and several steps have been taken to ensure data security in IPCL network. All incoming and outgoing network traffic are monitored and controlled through a modern Firewall with defined web and application protection policies. Accesses to internet are restricted only for domain authenticated users which is SSO (Single-Sign-On) based. Users can access resources remotely only through VPN (Virtual Private Network) as per the requirement and duly authorized. All the Laptop/Desktop/Server have antivirus application protection system which prevent, detect and remove malware like viruses, worms, spyware etc. Every laptop/desktop critical data are put under automatic data back up system using google tool.

All the systems and applications have password policies enforced. Mail accesses in handheld device are allowed through device policy. Critical applications like SAP, Website & Customer Portal are hosted in data centres of AWS and TCL which have Multi-Tier Cloud Security. Vulnerability Assessment & Penetration Testing (VAPT) is conducted once in a year by security experts and its findings are attended to, to mitigate any risk. Due to the steps taken above, we are pleased to note that in 2019-20, we did not have any security incident.

To sum it all, we are on our way to become a digital IPCL in line with Digital India plan of the country.

Edit

Dishergarh Power Station

India Power Corporation Ltd. (IPCL), formerly known as DPSC Limited, incorporated in 1919, is set to become India’s leading power generation and utility company. The company has actively forayed into a diversified portfolio, with renewable and conventional modes of power generation, distribution & power trading.

IPCL has been commissioned 1x12MW Thermal Power Plant on 25.09.2012 within the existing boundary of Dishergarh Power Station with AFBC Technology Boiler which was supplied by M/s Cheema Boiler Limited and Turbine was supplied by M/s Siemens Limited. The power generated from the plant is fed to Dishergarh Grid for supplying to IPCL licensing area.

Salient Features Of The Power Plant:

12 MW Thermal Power Plant was set up only in an area of one acres approximately after demolition of 10 old boilers which were installed mid-20 th Century.

Project financed by IDBI Bank limited.

Existing Water Allocation (DVC) utilized for 12 MW Power Plant.

Evacuation through existing Grid Substation of Dishergarh to Licensing Area.

Environmental Clearance obtained from Dept. of Environment Govt. West Bengal Consent to Operate and renewals has been obtained from West Bengal Pollution Control Board.

Existing Factory License issued Directorate of Factory, Govt. of West Bengal in the year 1924 has been continued.

Boiler Steaming Certificate obtained from Directorate of Boiler, Govt. of West Bengal.

Electrical Charging Clearance obtained from Directorate of Electricity, Govt. of West Bengal.

In-principle investment approval obtained from West Bengal State Electricity Regulatory Commission.

COD is declared on 25.09.2013.

Edit

Renewable Power Generation

Our contribution in India’s Power Generation sector

The Company has asset-light renewable energy portfolio with long term PPAs in place. It has over a decade of experience in operating wind energy projects with 35.2 MW operational generation capacities in Gujarat and Karnataka. The Company in association with West Bengal Green Energy Development Corporation Limited has set up a Photo Voltaic Solar Power Plant, located in Jamuria area of West Bengal with an annual capacity of 2 MW. It is a first grid connected solar power plant in India. India Power Corporation Limited through IPCL Pte Limited, has during the year under review partnered to implement the first 100 MW Solar Project in Albania, a project launched by the Government of Albania to diversify energy resources in Albania and lead the way in turning Albania into a centre of solar power.

Our Future Growth Strategy The Company is continuously looking for opportunities in renewable space since it wants to maintain a balance of both conventional and non-conventional sources of energy. In addition, the Company is also actively looking at opportunities in Waste to Energy segment.

Edit

India Power Corporation Limited has over a decade of experience in operating wind energy projects. It has installed 35.2 MW Wind Power plants. Just as sustainability is at the core of any renewable energy business, India Power too believes in harnessing the good in energy to add quality to everyday life. People are our strength and partners for growth. The Company believes in progressing with its partners in addressing the evolving needs in today’s changing energy landscape.

Key Highlights

- The Company operates the wind projects on an asset-light model, wherein, it exclusively administers the wind farms for a fixed lease payment.

- All projects have secured long-term PPAs

- The Company ensures energy availability of above 90% and a Plant Load Factor (PLF) of over 18% across all units

State |

District |

Project Capacity |

Commercial Operation Date |

PPA Terms & Authority |

Tariff INR/kwh |

|---|---|---|---|---|---|

|

Karnataka

|

Chitradurga

|

10.4MW

|

March 2006

|

20 Years-executed with Bengalore Electricity Supply Company Limited

|

3.4

|

|

Gujarat

|

Rajkot,Jamnagar and Kutch

|

24.8MW

|

March 2007

|

20 Years-executed with Gujarat Urja Vikas Nigam Limited

|

3.37

|

Edit

West Bengal Green Energy Development Corporation Limited in association with India Power Corporation Limited had set up a 2 MW Photo Voltaic solar power plant in Jamuria, West Bengal. Power generated from this solar plant is directly fed into the Company’s Distribution License area at Asansol. The solar plant has helped to reduce 0.7 metric tons of CO2 emission per day.

Key Highlights

- First in India to cross the Megawatt threshold in solar

- First grid connected solar power plant in India

- First significant climate responsive project in South Asia

Edit

Smart Meter Offering from IPCL

IPCL has been one of the early adopters of digital transformation in utility sector. In its efforts to convert its grid to smart grid, it has adopted smart meter solutions with consumers, IOT devices in its distribution transformers (DT) and even 3 phase smart meters in its grid, SCADA etc. To build on such implementations, it further implemented business intelligence solutions and developed its own outage and power quality management systems. While implementing such solutions, it has developed capability and knowhow to help the entire utility sector in the country to reap the benefits of digitalization.

Such deployments are essential for reducing losses of over 30% in several state utilities to the target of 15%. Also, Reduction in AT&C loss shall help arrest yearly leakage of state utilities by USD 8-10 billion on an yearly basis.40 GW of rooftop solar installation is planned by 2022 and smar meters can play a crucial role in net-metering.

Our country is in the process of implementing 250 million smart meters in the next few years. To contribute in this effort, IPCL has come forward with its in-house developed expertise to help the entire utility sector to achieve this goal.

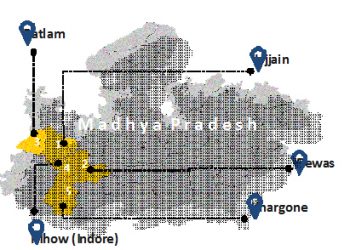

IPCL not only has plans to convert all its consumers to smart meters, it has also bagged a contract through competitive bidding to implement 350,000 smart meters in five towns – Ujjain, Ratlam, Dewas, Khargone and Mhow – in Madhya Pradesh.

In implementing such a solution, it has been a single window implementor covering :

- Consumer Indexing.

- Smart Pre-paid and post paid meter deployment.

- O&M Services for 5 years.

- Developement of Master Control Center and Mini Control Centers.

IPCL also offers Data Analytics solution using smart meter data which can benefit consumers & discom and take customer experience to the next level.